Blog

Introduction

The garment industry is considered a labor intensive industry which employs a large workforce and hence deemed critical to economic activities in our country. Its classified into textile industry in readymade and unstitched category which also includes shoes, although looking at it from storage & logistic point of few, they fall into two different categories.

Garment industry due to its nature make it require adapted storage systems. In this blog we will explore the most common solution of manual picking and the new kid on the blog garment on hanger automation.

The garment industry is considered one of the most competitive and demanding industry worldwide, as it has short life cycle, frequent changes in trends and has an impulse purchasing component. The purchasing is related to seasons & festivals with sudden upsurge in demand. Hence the logistic process changes accordingly.

Online shopping has added another element to it. The complete chain has been modified as it has created a more complex logistic process by having large distribution centers to meet consumer demand of shorter time frames. Hence it requires optimized warehouse that allows product rotation and quick time delivery as demanded by the customer.

So, far this process is done through manual storage or picking system. Though this system is widely prevalent even today, garment automation for hanging products and sortation system for folded products are gaining traction as the industry fights to be competitive and retain its customer base.

Let us explore the 2 options in picking solutions.

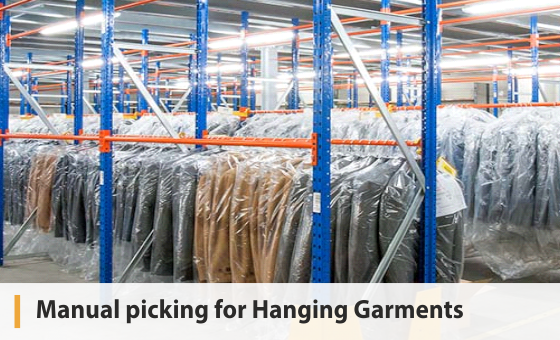

1) Manual picking for Hanging Garments

The most economical & efficient system for manual picking is long span system with hangers. It helps maintain its original shape in perfect condition. The system is completely adjustable and adaptable and can configured to customer’s requirements with the possibility of increasing levels in height & length. It’s a basic modular section that has bars which acts as hangers for cloths. The modules are replicated as required.

Each items are hung on beams or bars in parallel which helps maintain its original shape while the system remains compact and efficient. The system can easily accommodate different shapes and sizes of material.

In case of folded products, long span is converted to holding cartoons, crates large totes by having metal shelves on which they rest. Again it is highly adjustable and adaptable system with direct access to all its products.

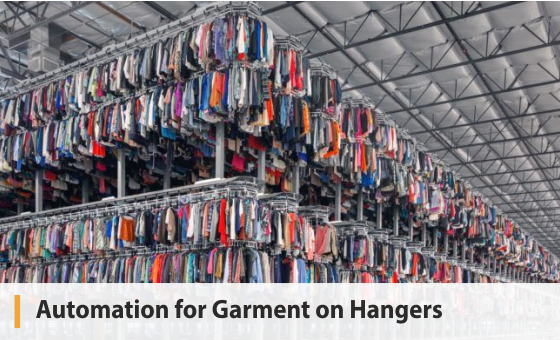

2) Automation for Garment on Hangers

The new kids we mentioned above is the GOH or garments on hanger automation system. The system stores and retrieve hangers via automation. Some of the major advantages of the system are

Folded garments are stored on long span shelving but their storage and retrieval can be speeded up by having conveyor and sortation systems.

Hope this insight can help you decide the most adaptable system for your business. Call us to discuss further on how we can help you take the right decision, the timelines & cost involved.

call us for a free consultation without obligation. For more information on storage solutions products visit jaystoargesolutions.com

Call us now +91-9146064222 / 23 / 61 / 62 / 63 / 64 or email us sales@jaystoragesolutions.com to fix an appointment for a short 30 minutes VC with our sales team and learn how we can help you with solving a big problem of small items.

Look forward to hearing from you. Until next time…

Contact Now